Roller Systems

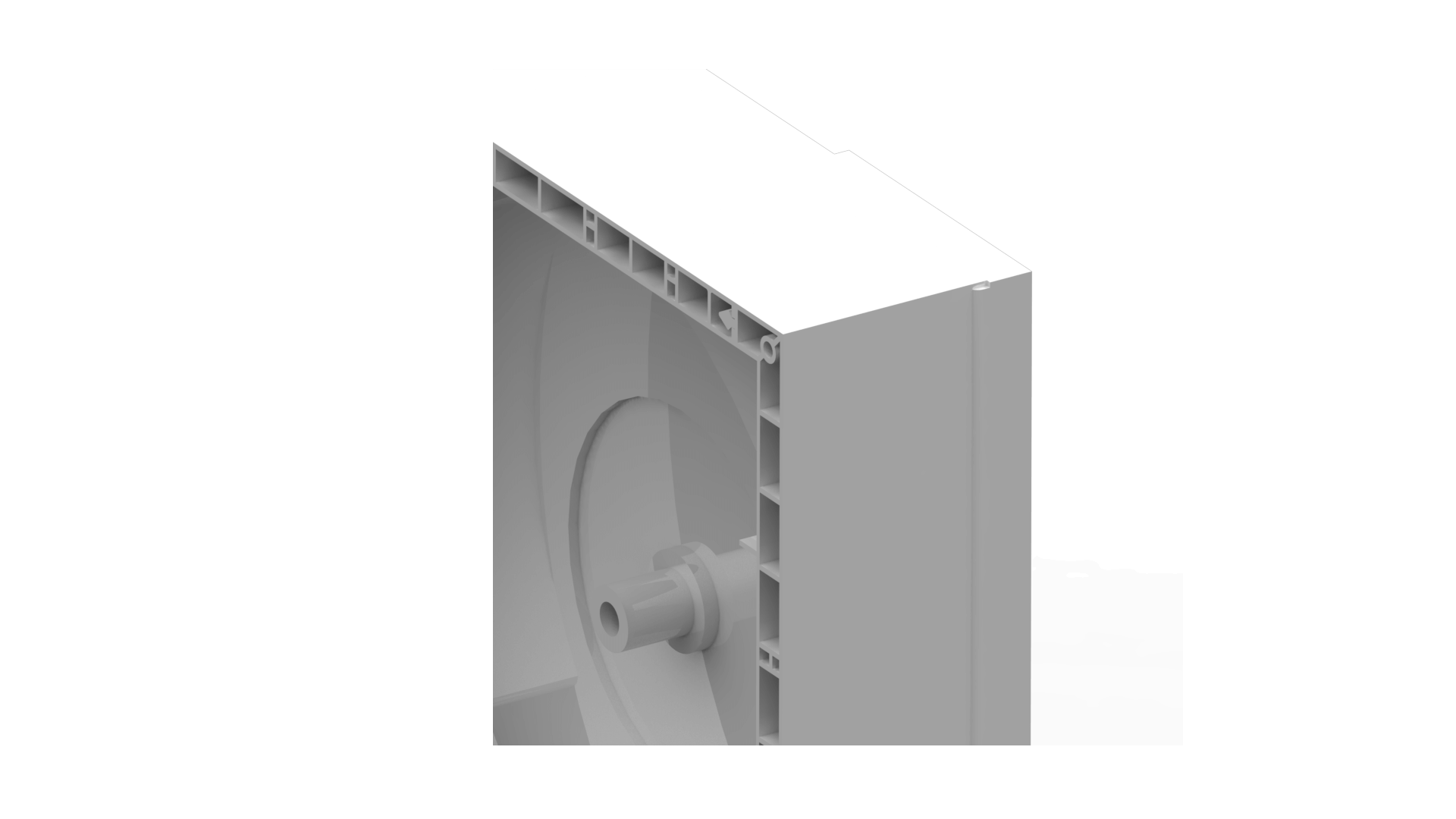

Roller System Maintenance Technoplast

Roller System Maintenance Technoplast

Maintaining Technoplast systems is easy and practical, thanks to the detachable guides (slides) they feature. These guides allow for quick and easy replacement during maintenance or repairs, without the need for complex disassembly procedures. Additionally, the installation of the channels can be done with special screws that have a plastic head, eliminating the need for screwing. If needed, replacement or maintenance of the channels can be easily performed after installation.

Material Traceability Systems

Material Traceability Systems

Technoplast implements modern traceability systems for every material produced. Each product carries a production number, allowing full tracking of its manufacturing process and quality control from production to delivery. This system ensures transparency and reliability of the company’s products.

Design Features

Design Features

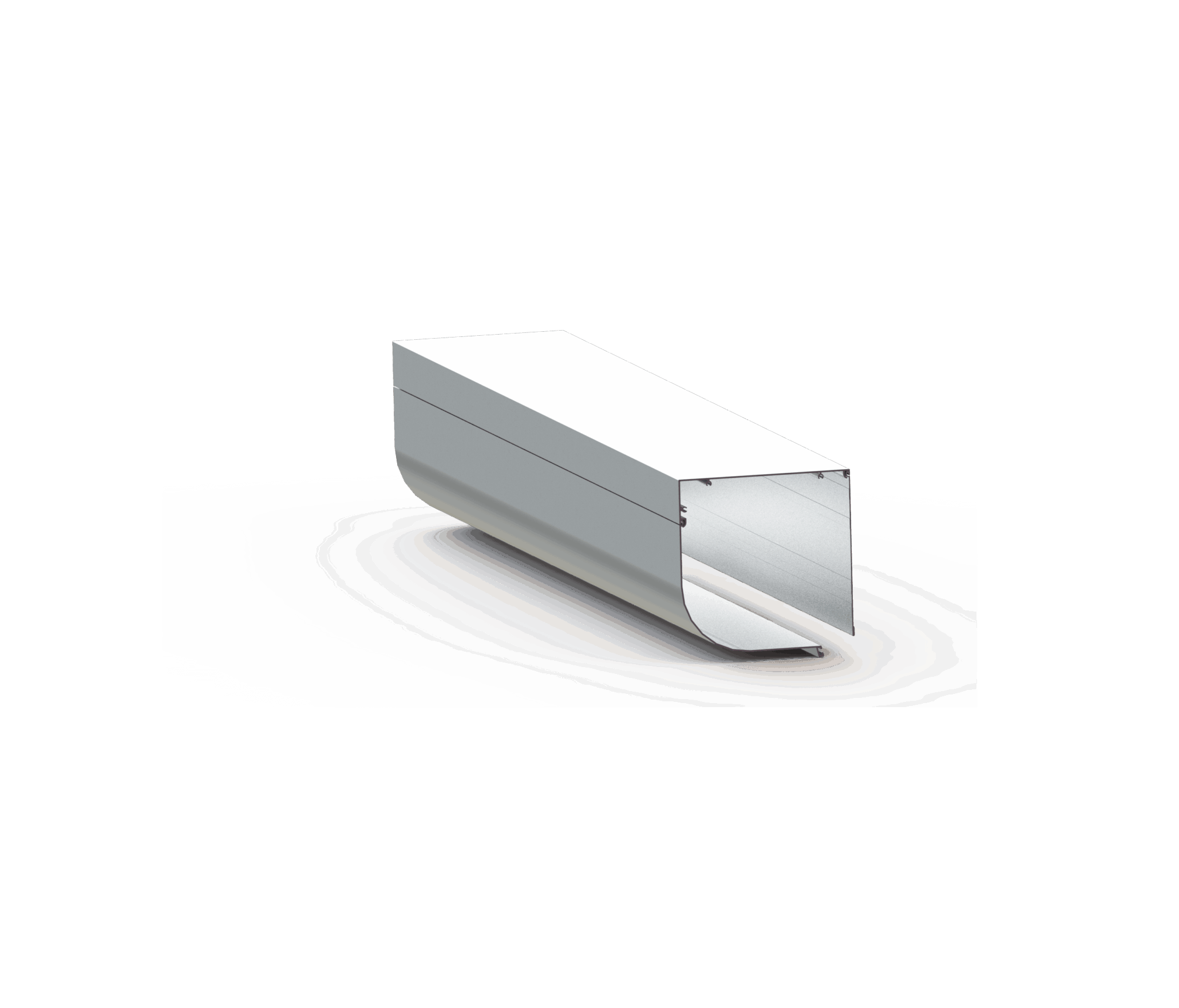

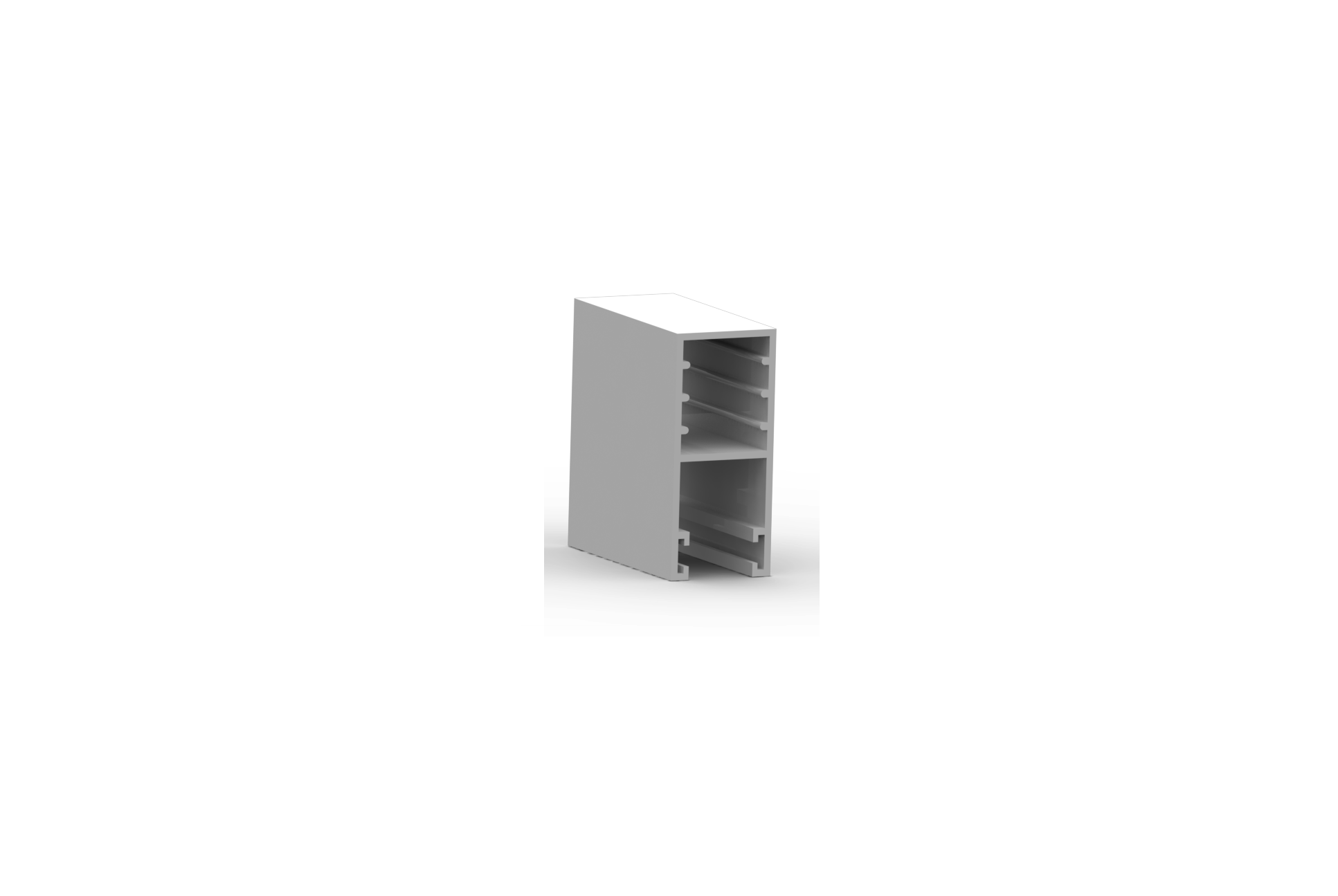

One of the innovative features of Technoplast’s shutters is the special ribbing that prevents the appearance of lines between the shutter surfaces, ensuring a uniform and aesthetically flawless appearance. Additionally, the side connections (side panels) are precision-engineered not only to provide a modern, minimalist look but also to offer extra stability and safety during shutter transportation. This ribbing also prevents air infiltration, enhancing the energy efficiency of the shutters.

Construction Quality and Materials

Construction Quality and Materials

Technoplast’s shutters are made from top-quality materials produced by the company (Compound PVC) with strict specifications. The materials are known for their durability and rigidity, while offering protection against UV rays, preserving their strength and aesthetic appearance for long periods. Additionally, the shutters are designed to provide an ideal weight balance, making their installation and operation more durable and efficient.

Premium Energy Efficiency

Premium Energy Efficiency

Technoplast’s roller systems are certified by Aristotle University of Thessaloniki for their superior performance, featuring one of the lowest thermal transmittance coefficients in Europe, at just 0.609 W/(m² * K). This ensures excellent energy efficiency, helping reduce heat loss and improve thermal insulation.

Additionally, Technoplast’s manufacturing process is supervised by independent authorities through ISO management systems, ensuring both manufacturing quality and the environmental footprint of the company, delivering high-quality and sustainable products.

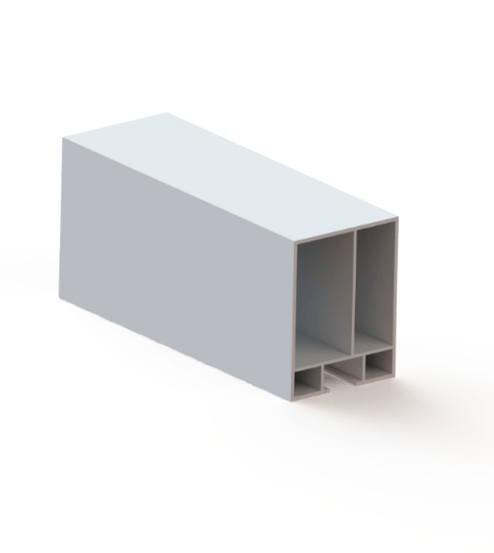

Custom Solutions

Custom Solutions

Technoplast offers complete systems for every application, with specific cross-sections tailored to each need. This means that manufacturers do not need to adjust the product during installation, as each roller system is designed to meet specific requirements, saving both time and money.

Production in Greece and Research & Development

Production in Greece and Research & Development

Technoplast’s products are entirely manufactured in Greece, with the contribution of the Research and Development (R&D) team. The R&D team ensures that products continuously evolve, addressing the modern needs of the market and providing solutions that exceed expectations.